What is HIRA? Understanding the Full Form and Meaning

HIRA stands for Hazard Identification and Risk Assessment. Think of it as your workplace’s safety crystal ball—not for predicting the future, but for systematically spotting potential dangers before they turn into real accidents.

At its core, HIRA is a proactive approach that helps organisations answer three fundamental questions:

- What can go wrong?

- How likely is it to happen?

- How bad could the consequences be?

Unlike reactive safety measures that kick in after something goes wrong, HIRA puts you ahead of the curve. It’s the difference between installing fire extinguishers after a fire and making sure combustible materials are properly stored in the first place.

What is HIRA in Safety? The Real-World Application

When safety professionals talk about HIRA in safety contexts, they’re referring to a structured methodology that’s become the backbone of workplace safety programs across industries. From construction sites to chemical plants, pharmaceutical facilities to oil rigs, HIRA provides the framework that keeps people safe.

Here’s what makes HIRA particularly valuable: it’s not just about ticking boxes on a compliance form. When done right, HIRA becomes ingrained in your organisation’s culture. Workers start thinking proactively about hazards. Managers make decisions with safety implications in mind. The entire operation becomes more aware, more prepared, and ultimately safer.

The process involves documenting every potential hazard, assessing the risks associated with each one, and implementing control measures to manage those risks. But it doesn’t stop there—HIRA is a living process that evolves as your workplace changes.

The Four Essential Steps of the HIRA Process

Understanding HIRA is one thing, but implementing it effectively requires following a systematic approach. Here’s how the process typically unfolds:

Step 1: Classify and Define Work Activities

Before you can identify hazards, you need to know exactly what activities are happening in your workplace. This means breaking down every task, routine or non-routine, into manageable components.

Walk through your facility. Document everything—from daily operations like equipment startup procedures to occasional tasks like tank cleaning or maintenance work. Don’t forget about activities that happen infrequently; those often carry hidden risks because workers might not be as familiar with the proper procedures.

This step also involves gathering critical information: process flow diagrams, safety data sheets, standard operating procedures, and even historical incident reports. The more comprehensive your documentation, the more effective your hazard identification will be.

Step 2: Identify the Hazards

Now comes the detective work. Hazard identification requires you to look at each activity and ask, “What could cause harm here?”

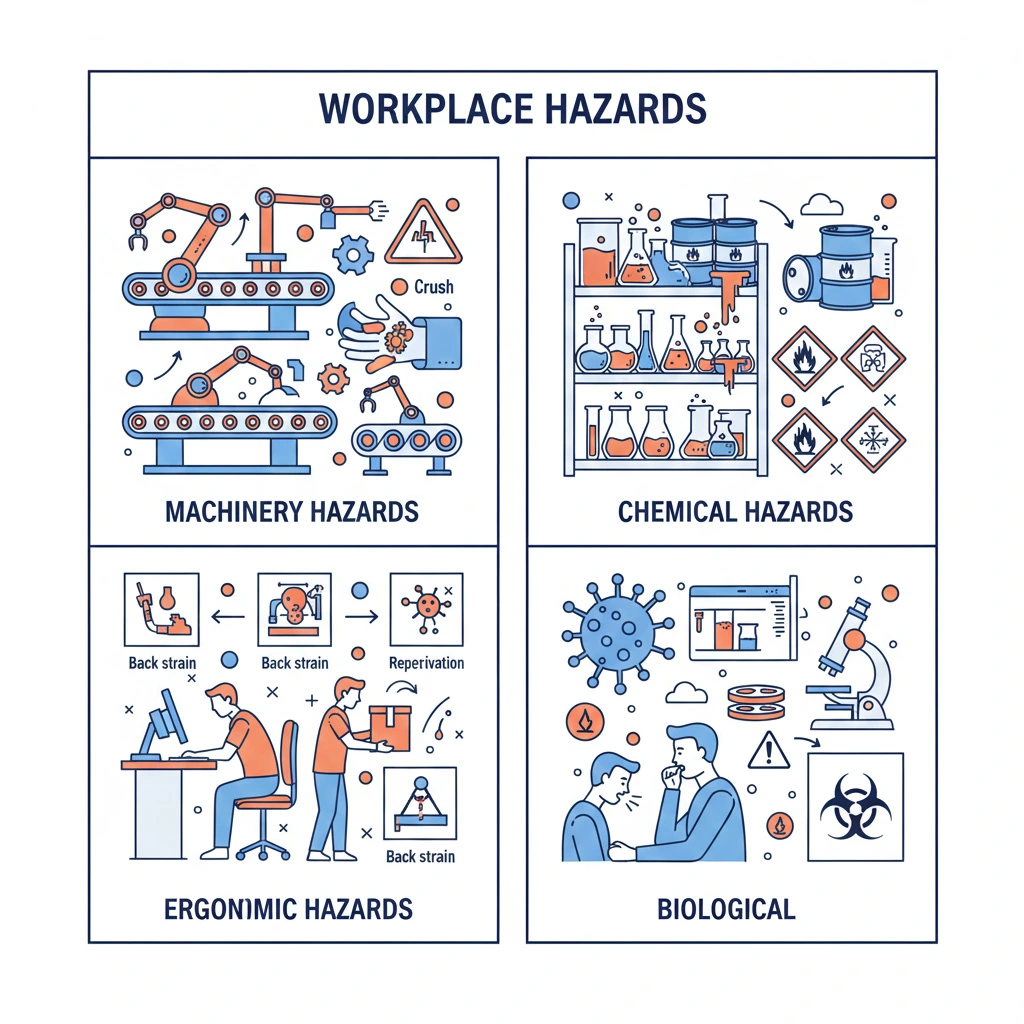

Hazards typically fall into several categories:

- Physical hazards: Machinery with moving parts, slippery surfaces, excessive noise, extreme temperatures

- Chemical hazards: Toxic substances, flammable materials, corrosive agents

- Biological hazards: Bacteria, viruses, mold, or exposure to bodily fluids

- Ergonomic hazards: Repetitive motions, poor workstation design, heavy lifting

- Psychosocial hazards: Work-related stress, workplace violence, fatigue from long shifts

The key here is thoroughness. Talk to the people who do the work every day—they often spot hazards that management might overlook. Review past accident reports and near-miss incidents. Conduct physical inspections of the workplace. Use checklists and established hazard identification techniques like HAZOP studies when appropriate.

Step 3: Conduct Risk Assessment

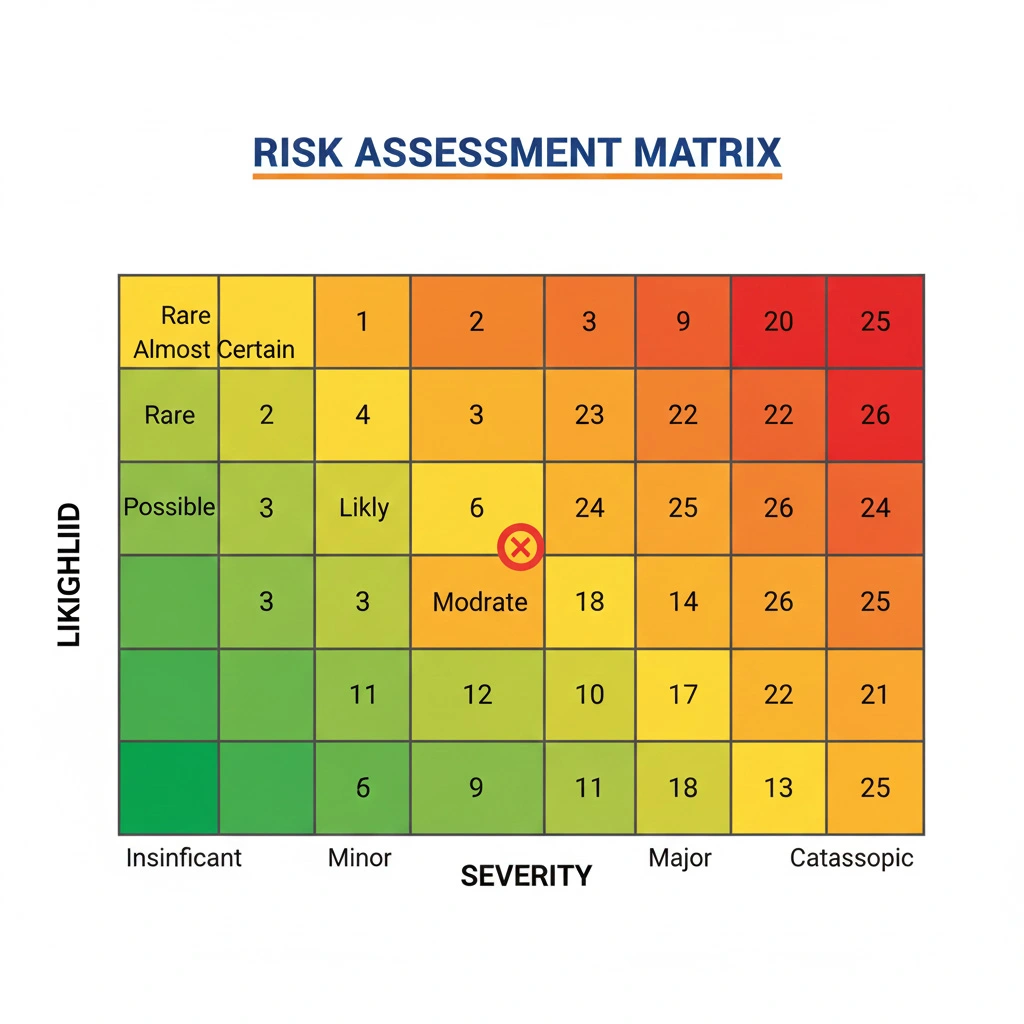

Once you’ve identified the hazards, you need to understand the actual risk they pose. Risk is essentially a combination of two factors:

- Likelihood: How probable is it that this hazard will cause harm?

- Severity: If harm does occur, how serious will the consequences be?

Most organisations use a risk matrix to quantify this. You’ll assign a numerical rating to both likelihood and severity (typically on a scale of 1-5), then multiply them to get a risk score. This score determines whether a risk is:

- Low risk (score under 5): Acceptable with existing controls

- Medium risk (score 5-9): Requires monitoring and may need additional controls

- High risk (score 10-19): Immediate attention required

- Extreme risk (score 20+): Work should stop until controls are implemented

For example, a chemical spill in a facility handling hazardous materials might have a moderate likelihood (say, a 3 out of 5) but severe consequences (5 out of 5), giving you a risk score of 15—firmly in the high-risk category requiring immediate action.

Step 4: Implement Control Measures

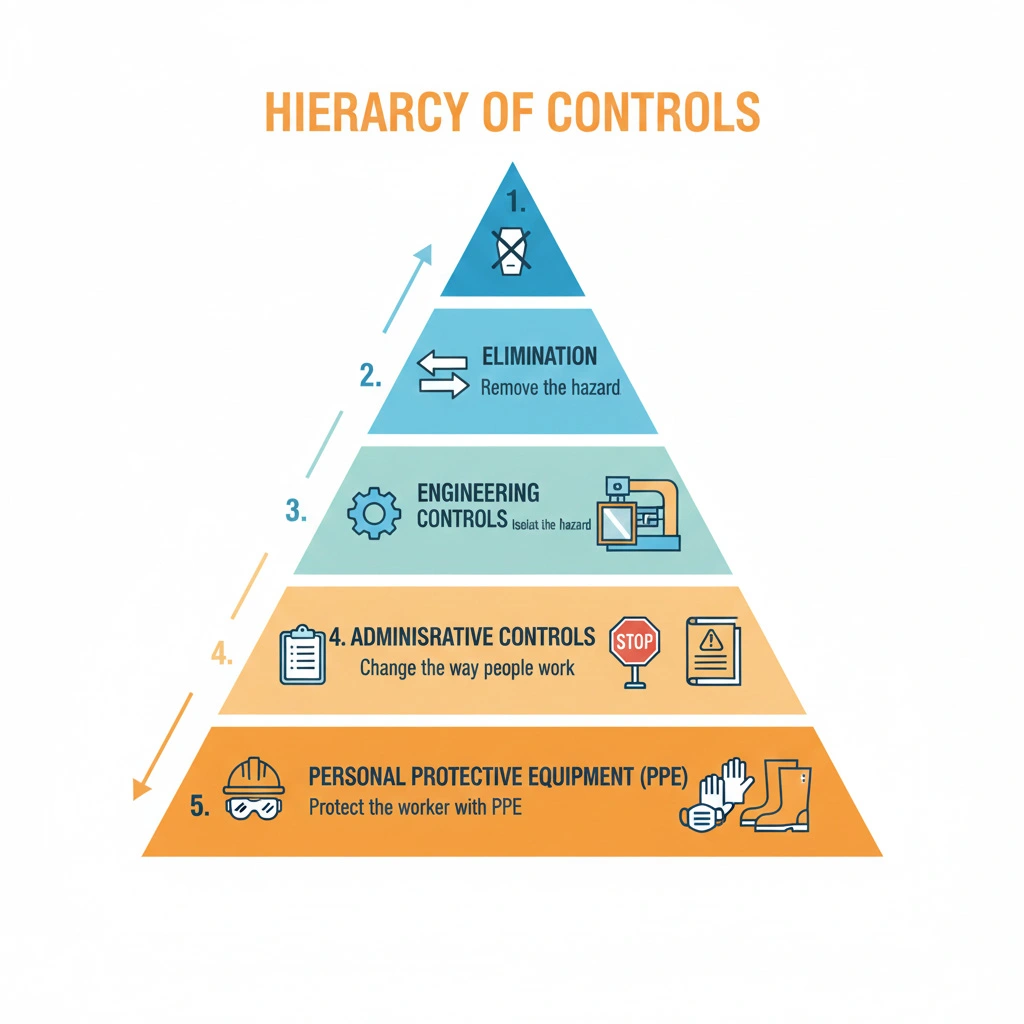

Here’s where theory meets practice. For each identified risk, especially those rated medium or higher, you need to implement controls. The hierarchy of controls provides a roadmap, from most to least effective:

- Elimination: Remove the hazard entirely (always the best option when possible)

- Substitution: Replace the hazard with something less dangerous

- Engineering controls: Isolate people from the hazard through physical changes (machine guards, ventilation systems)

- Administrative controls: Change work processes, implement training, create safety procedures

- Personal Protective Equipment (PPE): The last line of defense when other controls aren’t sufficient

A practical example: If workers are exposed to harmful chemical vapors, elimination might mean finding a safer alternative chemical. If that’s not possible, engineering controls like installing a proper ventilation system come next. Administrative controls would include limiting exposure time and training workers on proper handling. PPE—in this case, respirators—serves as the final protective layer.

Importantly, this step doesn’t end with implementation. You need to monitor the effectiveness of these controls, update them as conditions change, and document everything meticulously.

Why HIRA Matters: The Benefits You Can’t Ignore

You might be thinking, “This sounds like a lot of work.” And you’re right—it is. But consider what you’re getting in return:

Accident Prevention: The most obvious benefit. By identifying and controlling hazards before they cause harm, you’re literally saving lives. Every risk that’s mitigated is a potential accident that won’t happen.

Cost Savings: Accidents are expensive. Medical costs, workers’ compensation claims, equipment damage, production downtime, legal fees, increased insurance premiums—the financial impact of workplace incidents adds up quickly. HIRA helps you avoid these costs entirely.

Regulatory Compliance: Many countries have legal requirements for workplace risk assessments. In the U.S., OSHA regulations implicitly require hazard assessment. The UK has explicit COSHH regulations. India’s Occupational Health and Safety Act mandates HIRA compliance. Conducting proper HIRA studies keeps you on the right side of the law.

Improved Productivity: Safe workplaces are more efficient workplaces. When workers feel safe, they’re more focused, more confident, and more productive. There’s less time lost to accidents, less disruption from investigations, and better employee morale.

Better Decision Making: HIRA provides objective data that informs business decisions. Planning a process change? HIRA helps you understand the safety implications. Considering new equipment? HIRA reveals potential risks before you make the purchase.

Enhanced Reputation: In today’s world, corporate social responsibility matters. Companies known for strong safety records attract better talent, win more contracts, and enjoy better relationships with regulators and communities.

HIRA vs. Other Safety Methodologies: What’s the Difference?

If you’re involved in safety management, you’ve probably encountered other acronyms like JSA, HAZOP, or FMEA. So where does HIRA fit in?

HIRA vs. JSA (Job Safety Analysis): JSA focuses specifically on individual job tasks, breaking them down step-by-step to identify hazards. HIRA is broader, encompassing entire processes, facilities, or operations. Think of JSA as a subset that can feed into your overall HIRA process.

HIRA vs. HAZOP (Hazard and Operability Study): HAZOP is more detailed and systematic, typically used in process industries to examine what could go wrong if process parameters deviate from design intent. It’s more rigorous and time-consuming than HIRA. Many organizations use HIRA for general risk assessment and HAZOP for critical processes where more detailed analysis is warranted.

HIRA vs. PHA (Process Hazard Analysis): In the United States, PHA is the term used to describe risk assessments that meet specific regulatory requirements under OSHA’s Process Safety Management standard. PHA is essentially HIRA with additional regulatory specifications attached.

The beauty of HIRA is its flexibility. It can incorporate elements from these other methodologies when needed, making it adaptable to various industries and contexts.

Types of HIRA: Tailoring the Approach to Your Needs

Not all risk assessments are created equal. Depending on your circumstances, you might conduct different types of HIRA:

Baseline Risk Assessment: This is your starting point—a comprehensive evaluation of all risks in your operation. It establishes your risk profile and identifies areas needing immediate attention. Most organizations conduct baseline assessments when they first implement HIRA or when starting new operations.

Issue-Based Risk Assessment: Sometimes called targeted assessments, these focus on specific concerns that arise. Maybe you’ve had a near-miss incident, or you’re investigating employee complaints about a particular hazard. Issue-based assessments let you quickly address specific problems.

Continuous Risk Assessment: Think of this as ongoing vigilance. As operations evolve, new equipment is installed, or processes change, continuous assessment ensures your risk management stays current. This often involves routine inspections and regular reviews of existing HIRA documentation.

Change-Based Risk Assessment: Triggered by significant changes—new chemicals, process modifications, facility expansions, or even changes in personnel. This assessment ensures that changes don’t inadvertently introduce new hazards or increase existing risks.

The most effective safety programs use all these types, creating a layered approach where comprehensive baseline assessments are supplemented by targeted and continuous evaluation.

Common Challenges in HIRA Implementation (and How to Overcome Them)

Let’s be honest—implementing HIRA isn’t always smooth sailing. Here are some challenges you might face and practical solutions:

Challenge 1: Lack of Management Commitment

If leadership doesn’t prioritize safety, HIRA becomes a paper exercise that nobody takes seriously. The solution? Make the business case clear. Present data on accident costs versus prevention costs. Highlight liability concerns. Show examples from competitors who’ve suffered due to inadequate risk assessment.

Challenge 2: Insufficient Resources

Conducting thorough HIRA takes time and expertise. Organisations sometimes try to cut corners, assigning the task to someone who’s already overloaded or lacks proper training. The fix: Invest in proper training for your HIRA team. Consider bringing in external consultants for your initial baseline assessment. Budget adequate time for the process—rushing it defeats the purpose.

Challenge 3: Employee Reluctance

Workers might view HIRA as just more paperwork or worry that identifying hazards will make them look careless. Counter this by emphasising that HIRA is about systemic improvements, not individual blame. Involve employees in the process from the start. When workers see their input leading to tangible safety improvements, buy-in follows naturally.

Challenge 4: Documentation Overload

HIRA generates lots of paperwork, which can become overwhelming. Modern solutions include digital HIRA management systems that centralise documentation, track action items, and generate reports automatically. Even simple spreadsheet templates can help if implemented consistently.

Challenge 5: Keeping HIRA Current

A common mistake is treating HIRA as a one-and-done exercise. Workplaces change constantly, and your risk assessment needs to change with them. The solution is building review cycles into your management system. Set calendar reminders for annual reviews. Tie HIRA updates to your management of change process. Make it part of your organizational rhythm.

Industry-Specific Applications of HIRA

While the fundamental principles of HIRA remain constant, its application varies across industries:

Construction: HIRA in construction focuses heavily on changing conditions. Each project phase brings new hazards—excavation work, scaffolding, working at heights, heavy equipment operation. Construction HIRA needs frequent updating as work progresses.

Chemical and Pharmaceutical Manufacturing: Here, HIRA deals extensively with chemical hazards, reaction hazards, and process safety. Integration with HAZOP studies is common, and regulatory scrutiny is intense.

Oil and Gas: The focus shifts to high-consequence, low-probability events—explosions, fires, toxic releases. Quantitative risk assessment techniques often supplement traditional HIRA.

Healthcare: Biological hazards, sharps injuries, patient handling ergonomics, and workplace violence dominate healthcare HIRA. There’s also growing attention to psychological hazards from the stressful nature of healthcare work.

Food Industry: Contamination risks, allergen control, equipment cleaning, and temperature control are key HIRA considerations, often overlapping with HACCP (Hazard Analysis Critical Control Points) programs.

Understanding your industry’s specific hazard profile helps you tailor your HIRA approach for maximum effectiveness.

Best Practices for Effective HIRA Implementation

Want to ensure your HIRA program delivers real results? Follow these proven practices:

- Form a Multidisciplinary Team

Include people from operations, maintenance, safety, engineering, and frontline workers. Different perspectives reveal different hazards.

- Use Structured Methodologies

Don’t just wing it. Use established techniques like checklists, “what-if” analysis, or formal HAZOP procedures. Structure ensures nothing gets missed.

- Prioritize Based on Risk Levels

You can’t fix everything at once. Use your risk assessment scores to focus resources where they’ll have the most impact.

- Document Thoroughly

Maintain detailed records of identified hazards, risk assessments, control measures, and review dates. Good documentation proves compliance and supports continuous improvement.

- Communicate Results

Share HIRA findings with everyone affected. Workers need to know about hazards in their area and the controls in place. Management needs to understand resource requirements for risk reduction.

- Follow Up on Action Items

Identifying risks is pointless if you don’t implement the recommended controls. Establish accountability, set deadlines, and track completion.

- Review and Update Regularly

Schedule periodic reviews—at minimum annually, but more often for high-risk operations. Also trigger reviews when significant changes occur.

- Learn from Incidents

When accidents or near-misses occur despite your HIRA, investigate thoroughly and update your assessment. These are opportunities to refine your process.

The Future of HIRA: Digital Tools and Emerging Trends

Safety management is evolving, and HIRA is evolving with it. Here are some trends shaping the future:

Digital HIRA Platforms: Cloud-based software is replacing paper forms and spreadsheets. These platforms enable real-time updates, automated workflows, mobile access for field assessments, and powerful analytics to identify trends.

Predictive Analytics: Machine learning algorithms can analyse historical incident data, near-misses, and inspection findings to predict where future risks are most likely to emerge.

Integration with IoT: Sensors throughout facilities continuously monitor conditions—temperature, pressure, gas concentrations, noise levels. When parameters approach dangerous levels, automated alerts can trigger an immediate response.

Virtual Reality Training: VR lets workers experience hazardous scenarios in safe environments, improving their ability to recognise risks during actual HIRA assessments.

Behavioral Safety Integration: Modern HIRA increasingly considers human factors—fatigue, decision-making under stress, organisational culture. This psychological dimension complements traditional hazard identification.

Simplified User Interfaces: Recognising that many workers aren’t safety specialists, new tools feature intuitive interfaces with visual prompts, making HIRA more accessible to frontline employees.

These innovations don’t replace the fundamentals of HIRA—they enhance the process, making it more efficient, accurate, and accessible.

Getting Started with HIRA: Your Action Plan

Ready to implement or improve HIRA in your organisation? Here’s a practical roadmap:

Month 1: Preparation

- Secure management commitment and budget

- Form your HIRA team

- Provide training on HIRA methodology

- Gather existing documentation (SOPs, incident reports, floor plans)

Month 2-3: Baseline Assessment

- Conduct systematic workplace inspections

- Interview workers and supervisors

- Identify and document all hazards

- Perform initial risk assessments

Month 4: Control Measure Development

- Prioritize risks based on assessment scores

- Develop control measure recommendations

- Estimate implementation costs and timelines

- Present findings to management for approval

Month 5-6: Implementation

- Begin implementing approved control measures

- Start with highest-risk items

- Track progress against action items

- Communicate changes to affected workers

Ongoing: Maintenance and Improvement

- Conduct regular reviews (quarterly for high-risk, annually for others)

- Update assessments when changes occur

- Analyze effectiveness of controls

- Refine your process based on lessons learned

Remember, HIRA is a journey, not a destination. Your first assessment won’t be perfect, and that’s okay. The key is to start, learn, and continuously improve.

Frequently Asked Questions About HIRA

Q: How often should HIRA be conducted?

At minimum, review your HIRA annually. However, you should also update it whenever significant changes occur—new equipment, process modifications, after incidents, or when regulatory requirements change. High-risk operations may warrant more frequent reviews.

Q: Who should conduct HIRA?

Ideally, a multidisciplinary team that includes safety professionals, operational managers, engineers, supervisors, and frontline workers. For specialized processes, you might also need subject matter experts or external consultants.

Q: Is HIRA legally required?

This varies by country and industry. In India, it’s mandated under the Occupational Health and Safety Act. In the U.S., while OSHA doesn’t use the term “HIRA” specifically, the regulations require employers to identify and assess hazards. The UK’s COSHH regulations explicitly require risk assessments. Check your local regulations for specific requirements.

Q: How long does a HIRA take?

It depends on the size and complexity of your operation. A small facility might complete a baseline assessment in a few weeks, while a large chemical plant could take months. Don’t rush it—thoroughness is more important than speed.

Q: What’s the difference between a hazard and a risk?

A hazard is something with the potential to cause harm (like a chemical, a machine, or a working practice). Risk is the combination of the likelihood that the hazard will cause harm and the severity of that harm. You can have a high-hazard situation with low risk if proper controls are in place.

Q: Can small businesses benefit from HIRA?

Absolutely! The principles scale to any size operation. Small businesses might use simpler methods and less formal documentation, but the fundamental process of identifying hazards and assessing risks is universally valuable.

Wrapping Up: Making HIRA Work for You

Here’s the truth about HIRA: It’s not magic, and it’s not particularly complicated. What it is, though, is systematic, thorough, and when done right, remarkably effective at preventing workplace injuries and illnesses.

The organisations that get the most from HIRA are those that see it not as a compliance checkbox but as a genuine tool for protecting their people and improving their operations. They invest time in doing it properly. They involve the right people. They act on the findings. And perhaps most importantly, they treat it as an ongoing process rather than a one-time project.

Whether you’re just starting your HIRA journey or looking to enhance an existing program, remember that every step you take toward better hazard identification and risk assessment is a step toward a safer workplace. And in the end, that’s what matters most—getting everyone home safe at the end of the day.

So take that first step. Form that team. Conduct that assessment. Implement those controls. Your workers, your organization, and your bottom line will all be better for it.