You walk into a manufacturing plant, and the first thing you notice isn’t the machinery or the products being made—it’s how everyone seems genuinely focused on working safely. Hard hats are on, safety glasses in place, proper procedures being followed. That’s not by accident. That’s HSE at work.

If you’ve been hearing the term “HSE” thrown around in professional circles and found yourself nodding along without really understanding what it means, you’re not alone. Today, we’re breaking down everything about HSE—from its full form to why it matters so much in modern workplaces.

HSE Full Form: What Does HSE Stand For?

Let’s start with the basics. HSE stands for Health, Safety, and Environment. It’s not just another corporate acronym to memorize—it represents a comprehensive framework that organizations use to protect their people, their operations, and the world around them.

Think of HSE as three interconnected pillars:

Health focuses on protecting the physical, mental, and emotional well-being of everyone in the workplace. This includes preventing occupational diseases, managing workplace stress, ensuring proper ergonomics, and providing access to medical resources when needed.

Safety is all about preventing accidents and injuries. This means identifying hazards, implementing protective measures, training employees on safe work practices, and creating systems that catch potential problems before they cause harm.

Environment addresses the impact your organization has on the natural world. It covers everything from waste management and pollution control to energy efficiency and sustainable resource use.

Together, these three elements form a holistic approach to responsible business operations. You can’t really have one without the others—they work together like the legs of a stool.

Understanding HSE in Different Contexts

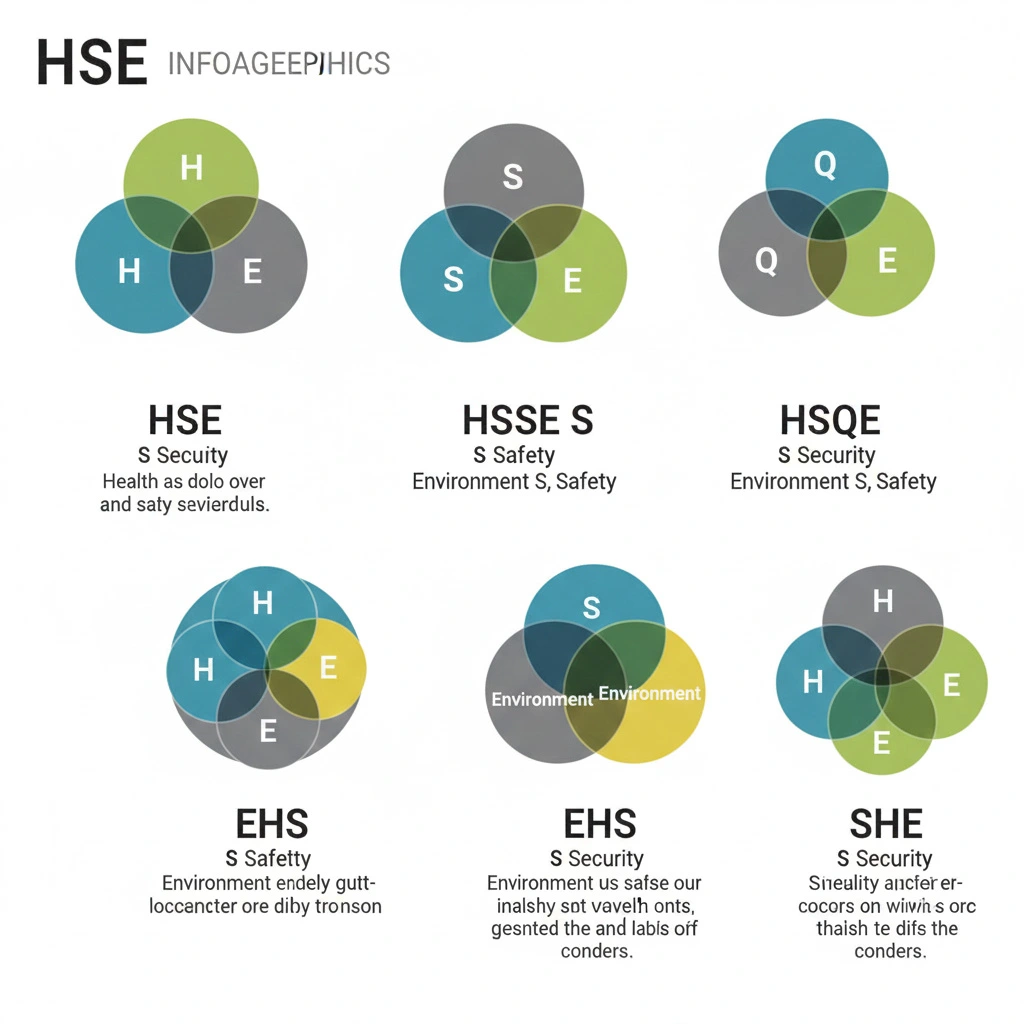

Here’s where it gets interesting. While HSE is the most common term, you’ll also encounter variations depending on where you are and what industry you’re in:

HSSE adds Security to the mix, recognizing that protecting people also means safeguarding them from threats like theft, cyber attacks, and unauthorized access. This is particularly relevant in industries dealing with sensitive information or high-value assets.

HSQE or HSEQ incorporates Quality into the framework, acknowledging that safety, health, environmental protection, and quality management are all interconnected aspects of operational excellence.

EHS (Environment, Health, and Safety) is essentially the same as HSE but with the order rearranged—you’ll see this more commonly in North American contexts.

SHE (Safety, Health, and Environment) is another variation that means the same thing.

Don’t let the alphabet soup confuse you. Regardless of which acronym your organization uses, the fundamental goal remains the same: creating workplaces that are safe for people and responsible toward the environment.

Why HSE Matters More Than Ever

Let me paint you a picture. In 1984, a catastrophic gas leak at a chemical plant in Bhopal, India killed thousands of people and injured hundreds of thousands more. In 1976, the Seveso disaster in Italy released toxic dioxin into the atmosphere, contaminating vast areas. These weren’t just accidents—they were wake-up calls that fundamentally changed how industries think about safety and environmental protection.

The chemical industry responded in 1985 with “Responsible Care,” a voluntary initiative that became the foundation of modern HSE management. Since then, the approach has evolved and spread across virtually every industry you can think of.

Today, HSE isn’t just about compliance or avoiding disasters. It’s become a strategic imperative that affects:

Your Bottom Line: Workplace accidents are incredibly expensive. Medical costs, workers’ compensation, legal fees, equipment damage, production downtime, increased insurance premiums—the financial impact adds up fast. Strong HSE programs prevent these costs before they occur.

Your Reputation: In an age where information spreads instantly, how you treat your workers and the environment directly impacts your brand. Companies with poor safety records or environmental violations face public backlash, customer boycotts, and difficulty attracting top talent.

Your Legal Standing: Regulations around workplace safety and environmental protection have become increasingly stringent worldwide. Non-compliance can result in hefty fines, criminal charges, and even shutdowns. HSE programs help you stay on the right side of the law.

Your People: This might sound obvious, but it’s worth saying: people perform better when they feel safe. Employees who trust that their organization genuinely cares about their wellbeing are more engaged, more productive, and more loyal.

Your Planet: With climate change and environmental degradation becoming increasingly urgent issues, businesses have a responsibility to minimize their ecological footprint. HSE provides the framework for sustainable operations.

The Three Pillars of HSE Explained in Detail

Let’s dig deeper into each component of HSE and what they actually mean in practice.

The Health Component: More Than Just Physical Wellness

When we talk about health in an HSE context, we’re looking at the complete picture of employee wellbeing. This isn’t just about avoiding immediate injuries—it’s about long-term health outcomes.

Occupational Health Programs monitor employees for work-related illnesses and exposure to harmful substances. This might include regular medical checkups, hearing tests for workers in noisy environments, respiratory monitoring for those exposed to dust or fumes, or blood tests for people handling toxic materials.

Ergonomics addresses how work is physically performed. Poor ergonomic design leads to repetitive strain injuries, back problems, and chronic pain that can affect workers for life. Good ergonomic practices involve designing workstations that fit the human body, providing proper equipment, and teaching workers how to perform tasks without putting unnecessary strain on their bodies.

Mental Health Support is increasingly recognized as a critical aspect of workplace health. Work-related stress, burnout, and mental health challenges affect productivity and quality of life. Progressive HSE programs include employee assistance programs, stress management resources, and cultures that destigmatize mental health discussions.

Wellness Initiatives go beyond preventing illness to actively promoting health. This might include fitness programs, healthy food options in cafeterias, smoking cessation support, or health education campaigns.

The goal is simple but profound: ensuring that work doesn’t make people sick, either immediately or over time.

The Safety Component: Prevention is Everything

Safety is probably what most people think of first when they hear HSE. It’s the visible stuff—hard hats, safety barriers, warning signs, emergency exits. But effective safety management goes much deeper than just providing equipment.

Hazard Identification is the foundation. You can’t protect against risks you haven’t recognized. This involves systematic workplace inspections, job safety analyses, employee input (since workers often know the hazards best), and reviewing incident data to spot patterns.

Risk Assessment takes identified hazards and evaluates how likely they are to cause harm and how severe that harm might be. This prioritization ensures resources go where they’re needed most.

Control Implementation is where the rubber meets the road. Following the hierarchy of controls (elimination, substitution, engineering controls, administrative controls, and PPE), organizations implement measures to manage risks. The best controls eliminate hazards entirely; the least effective simply provide personal protective equipment as a last line of defense.

Safety Training ensures everyone knows how to work safely. This includes general safety orientation for new employees, job-specific training for particular tasks, emergency response training, and regular refresher courses.

Incident Investigation learns from failures. When accidents or near-misses occur, thorough investigation identifies root causes and prevents recurrence. The focus is on fixing systems, not blaming individuals.

Emergency Preparedness plans for worst-case scenarios. Fire drills, evacuation plans, first aid training, emergency equipment maintenance, and crisis management protocols ensure that when something does go wrong, the response is swift and effective.

The Environment Component: Protecting Our Shared Home

The environmental aspect of HSE addresses how your operations affect the natural world. This has evolved from simple pollution control to comprehensive sustainability management.

Waste Management goes beyond just disposing of trash. It involves reducing waste at the source, reusing materials where possible, recycling what can’t be reused, and properly disposing of what remains—especially hazardous waste that could harm ecosystems.

Emissions Control manages what your operations release into the air. This includes greenhouse gases contributing to climate change, particulate matter affecting air quality, and other pollutants that can harm human health and the environment.

Water Management protects this precious resource. It involves treating wastewater before discharge, preventing contamination of groundwater, reducing water consumption, and managing stormwater runoff.

Energy Efficiency reduces your carbon footprint while cutting costs. This might involve upgrading equipment, optimizing processes, implementing renewable energy sources, or simply turning off lights when they’re not needed.

Resource Conservation recognizes that natural resources are finite. Using materials efficiently, sourcing sustainably, and considering the full lifecycle of products all contribute to environmental responsibility.

Biodiversity Protection considers impacts on local ecosystems. Construction projects might include wildlife corridors; operations near sensitive habitats take extra precautions; some organizations actively work to restore or enhance natural environments.

Regulatory Compliance ensures you meet environmental laws and regulations, which vary by location and industry but generally aim to protect air quality, water resources, and land from pollution and degradation.

HSE in Different Industries: Tailored Approaches

While the fundamental principles of HSE remain constant, how they’re applied varies significantly across industries. Let’s look at a few examples:

Construction Industry

Construction sites are dynamic environments where conditions change daily. HSE in construction focuses heavily on fall protection (the leading cause of construction deaths), excavation safety, electrical hazards, and managing multiple contractors working in the same space. Daily safety briefings, job hazard analyses, and strict PPE requirements are standard practice.

Oil and Gas Industry

The oil and gas sector deals with high-consequence risks—explosions, fires, toxic releases. HSE programs here incorporate rigorous process safety management, emergency response capabilities, and environmental monitoring. Given the remote locations of many operations, medical emergency preparedness and personnel safety in extreme environments are also critical.

Manufacturing

Manufacturing HSE focuses on machine safety, chemical handling, repetitive motion injuries, and maintaining consistent safety standards across multiple shifts. Lockout/tagout procedures, confined space entry protocols, and proper material handling are central concerns.

Healthcare

In healthcare, HSE addresses unique challenges like biological hazards, needlestick injuries, patient handling ergonomics, workplace violence, and proper disposal of medical waste. The COVID-19 pandemic highlighted just how critical healthcare HSE practices are.

Chemical Processing

Chemical plants implement layered safety systems including process hazard analyses, rigorous operating procedures, automated safety systems, and extensive emergency planning. Environmental concerns center on preventing releases, managing hazardous waste, and minimizing emissions.

What Does an HSE Officer Do? Roles and Responsibilities

If HSE is the framework, HSE Officers are the people who make it work. Let’s talk about what these professionals actually do day-to-day.

Policy Development: HSE Officers create and maintain the safety policies, procedures, and guidelines that govern workplace operations. They ensure these documents reflect current regulations and best practices while remaining practical for workers to follow.

Risk Assessments: They conduct systematic evaluations of workplace hazards, determining what risks exist, how severe they are, and what controls are needed. This involves workplace inspections, reviewing operational procedures, and analyzing incident data.

Training and Education: HSE Officers develop and deliver training programs covering everything from new employee orientations to specialized training on specific hazards. They ensure workers know not just what to do, but why it matters.

Compliance Monitoring: They stay current on evolving regulations and ensure the organization complies with legal requirements. This includes maintaining required documentation, submitting regulatory reports, and coordinating with government inspectors.

Incident Investigation: When accidents or near-misses occur, HSE Officers lead investigations to determine what happened, why it happened, and how to prevent it from happening again. They prepare reports documenting findings and recommended corrective actions.

Audits and Inspections: Regular workplace inspections identify hazards and verify that safety measures are working as intended. HSE Officers also prepare for and coordinate external audits.

Emergency Planning: They develop emergency response plans, coordinate drills, and ensure emergency equipment is maintained and accessible. When emergencies occur, they often lead the response.

Safety Communication: HSE Officers serve as a resource for employees, managers, and contractors on safety matters. They might run safety committees, publish safety bulletins, or conduct safety campaigns to keep attention focused on important issues.

Continuous Improvement: By analyzing trends in incident data, inspection findings, and worker feedback, HSE Officers identify opportunities to enhance safety performance. They recommend investments in new equipment, process changes, or additional training.

It’s a role that requires technical knowledge, communication skills, attention to detail, and the ability to balance safety requirements with operational needs. Good HSE Officers are problem-solvers who work collaboratively with all levels of the organization.

The HSE Management System: How It All Comes Together

Effective HSE doesn’t happen by chance—it requires a structured management system. Most organizations follow a model based on the Plan-Do-Check-Act cycle:

Plan: Establish your HSE policy, identify hazards and assess risks, set objectives and targets, and develop programs to achieve them. This is where you decide what you want to accomplish and how you’ll get there.

Do: Implement your plans. This means training people, providing resources, executing procedures, maintaining equipment, and integrating HSE into daily operations. Everyone from top management to frontline workers has a role to play.

Check: Monitor and measure your performance. Are you meeting your targets? Are controls working as intended? Regular audits, inspections, and performance reviews provide the data you need to answer these questions.

Act: Based on what you learned in the Check phase, make improvements. This might mean updating procedures, adding resources, providing additional training, or recognizing good performance. The cycle then begins again with revised plans.

This continuous improvement approach ensures that your HSE program evolves and gets better over time rather than remaining static.

Many organizations align their HSE management systems with international standards like ISO 45001 (occupational health and safety) and ISO 14001 (environmental management). These standards provide globally recognized frameworks and can lead to formal certification, demonstrating your commitment to HSE excellence.

Common HSE Challenges (And How to Overcome Them)

Even with the best intentions, organisations face obstacles in implementing effective HSE programs. Here are some common challenges and practical solutions:

Challenge: “Safety is a cost centre”

Some leaders view HSE as an expense rather than an investment. The solution is demonstrating the return on investment. Track and communicate the costs of incidents versus the costs of prevention. Calculate productivity gains from fewer injuries and less downtime. Show how good HSE performance attracts customers and talent.

Challenge: Complacency

When things have been safe for a while, people naturally let their guard down. Combat this through regular communication that keeps safety top of mind, recognize and reward good safety behaviors, share near-miss reports to remind people that hazards are still present, and vary your safety messages to keep them engaging.

Challenge: “We’re too busy”

Production pressures sometimes lead to shortcuts on safety. Address this by making HSE part of performance evaluations for all managers, establish that quality includes doing work safely, provide adequate time and resources for safe work, and empower workers to stop unsafe work without fear of retaliation.

Challenge: Inconsistent implementation

Safety varies between shifts, departments, or locations. Fix this through standard operating procedures that everyone follows, regular audits to identify inconsistencies, sharing best practices across the organization, and leadership visibility—when managers from different areas all emphasize the same messages, consistency follows.

Challenge: Language and cultural barriers

In diverse workplaces, ensuring everyone understands safety information can be difficult. Solutions include translating materials into relevant languages, using visual aids and videos that transcend language barriers, pairing workers with buddies who speak their language, and providing language training where feasible.

Challenge: Contractor management

Contractors may not be familiar with your safety requirements. Address this through formal contractor safety orientation, clear safety requirements in contracts, regular oversight of contractor work, and holding contractors to the same standards as your own employees.

Building a Strong HSE Culture

Here’s a truth that every safety professional knows: You can have the best policies and procedures in the world, but if your organizational culture doesn’t support them, they’re just paper.

A strong HSE culture exists when safety is truly valued—not just talked about, but demonstrated through actions at every level. Here’s what that looks like:

Leadership Commitment starts at the top. When executives participate in safety walks, include HSE in business reviews, allocate resources to safety initiatives, and hold themselves accountable for safety performance, it sends a powerful message.

Employee Involvement means workers aren’t just following rules—they’re active participants in creating a safe workplace. Encourage reporting of hazards and near-misses, invite input on safety procedures, include frontline workers on safety committees, and recognize safety contributions.

Open Communication creates an environment where people feel comfortable raising safety concerns without fear of negative consequences. Establish multiple reporting channels, respond promptly to concerns, share information about incidents and lessons learned, and celebrate safety successes.

Accountability means everyone understands their safety responsibilities and there are consequences for not fulfilling them—but the focus is on systemic issues rather than blaming individuals for errors that result from inadequate systems.

Continuous Learning treats every incident and near-miss as an opportunity to improve. Share lessons learned across the organization, conduct regular safety training, stay current on industry best practices, and benchmark against other organizations.

Integration embeds HSE into everything you do rather than treating it as separate. Include HSE in project planning from the start, consider safety implications in purchasing decisions, incorporate HSE into performance evaluations, and recognize that production and safety goals should align, not conflict.

The Business Case for HSE: Return on Investment

Let’s talk numbers, because sometimes that’s what it takes to secure buy-in for HSE initiatives.

Direct Cost Savings: According to research, for every dollar invested in workplace safety, companies save an average of four to six dollars. These savings come from reduced workers’ compensation claims, lower insurance premiums, less equipment damage, and decreased medical costs.

Indirect Cost Savings: The indirect costs of accidents often exceed direct costs by a factor of four or more. These include lost productivity, temporary worker costs, training replacement workers, administrative time investigating incidents, and the ripple effects on team morale and productivity.

Improved Productivity: Safe workplaces are more efficient workplaces. When workers aren’t worried about getting hurt, when equipment is well-maintained, when processes are properly controlled, work flows more smoothly. Studies have shown that companies with strong safety cultures also tend to have better overall operational performance.

Talent Attraction and Retention: Top performers want to work for companies that demonstrate genuine care for employees. A strong HSE record helps recruit better talent and reduces turnover, saving on recruitment and training costs.

Market Access: Many customers, especially large corporations and government entities, require suppliers to meet specific HSE standards. Strong HSE performance opens doors to business opportunities that wouldn’t otherwise be available.

Reduced Legal Liability: While you can’t entirely eliminate the risk of lawsuits, demonstrating that you took reasonable precautions to protect workers significantly reduces your exposure. Courts look more favorably on companies that can show systematic HSE efforts.

Brand Value: In an era of social media and corporate transparency, your reputation matters. Companies known for good HSE performance enjoy better public perception, easier community relations, and enhanced brand value.

HSE and Sustainability: The Connection

You might have noticed that HSE and sustainability initiatives often overlap, and that’s no coincidence. Both aim to ensure that today’s operations don’t compromise tomorrow’s opportunities.

The “E” in HSE directly addresses environmental sustainability—reducing pollution, conserving resources, and minimizing ecological impact. But the connection goes deeper than that.

Sustainable businesses are safer businesses. Process improvements that reduce waste often also reduce exposure to hazardous materials. Energy efficiency projects typically involve upgrading to equipment with better safety features. Sustainable sourcing reduces risks associated with hazardous substances.

Both focus on prevention. Just as HSE aims to prevent accidents before they occur, sustainability works to prevent environmental damage before it happens. The mindset of proactive risk management applies to both.

Both require long-term thinking. HSE considers the long-term health effects of today’s exposures. Sustainability considers the long-term environmental effects of today’s decisions. Neither accepts short-term gains at the expense of future well-being.

Both drive innovation. The challenge of maintaining safety while improving environmental performance often leads to creative solutions—new technologies, better processes, innovative materials—that provide competitive advantages.

Many organizations are integrating HSE with corporate social responsibility (CSR) and Environmental, Social, and Governance (ESG) initiatives, recognizing that these aren’t separate concerns but interconnected aspects of responsible business operations.

The Future of HSE: Trends and Technologies

HSE is constantly evolving. Here are some trends shaping its future:

Digital Transformation: Cloud-based HSE management systems enable real-time reporting, data analytics, and mobile access. Workers can report hazards from their smartphones. Managers can access dashboards showing safety metrics across multiple locations. Digital tools make HSE more efficient and accessible.

Wearable Technology: Smart helmets, vests, and watches can monitor worker location, detect falls, measure environmental conditions like heat stress or toxic gas exposure, and even remind workers to take breaks or hydrate. These devices provide early warning of potential problems.

Artificial Intelligence and Predictive Analytics: Machine learning algorithms can analyze incident data, inspection findings, and environmental factors to predict where the next accident is likely to occur. This allows preventive action before incidents happen.

Virtual and Augmented Reality: VR provides immersive safety training in hazardous scenarios without actual risk. AR can overlay safety information onto real-world views through smart glasses, showing workers proper procedures or highlighting hazards in their immediate environment.

Drones and Robotics: Unmanned systems can inspect dangerous locations—high structures, confined spaces, contaminated areas—without exposing workers to risk. They provide detailed visual documentation and can access places humans can’t safely go.

Internet of Things (IoT) sensors continuously monitor conditions—air quality, noise levels, temperature, equipment vibration, chemical concentrations. When parameters exceed safe thresholds, automated alerts trigger immediate response.

Focus on Psychological Health: Recognition is growing that mental health is just as important as physical safety. Progressive HSE programs now address work-related stress, fatigue management, workplace bullying, and psychological support.

Integration with Business Systems: HSE is moving from standalone programs to integrated elements of overall business management, connected with quality, operational efficiency, and financial performance.

These innovations don’t replace fundamental HSE principles—they enhance our ability to apply them more effectively.

HSE Certification and Standards: What You Need to Know

If you’re serious about HSE, you’ll eventually encounter various certification schemes and standards. Here’s what they mean:

ISO 45001 is the international standard for occupational health and safety management systems. It provides a framework for organizations to improve employee safety, reduce workplace risks, and create better working conditions. Achieving ISO 45001 certification demonstrates your commitment to worker safety through third-party verification.

ISO 14001 covers environmental management systems. It helps organizations minimize their environmental impact, comply with environmental regulations, and continually improve their environmental performance. Many organizations pursue both ISO 45001 and 14001 together for integrated HSE management.

NEBOSH (National Examination Board in Occupational Safety and Health) offers internationally recognized qualifications for safety professionals. The NEBOSH International General Certificate is particularly popular for those starting an HSE career.

IOSH (Institution of Occupational Safety and Health) provides professional membership and qualifications for safety practitioners, from frontline workers to senior executives.

OSHA Training (in the United States) includes OSHA 10-hour and 30-hour courses that cover workplace hazards and worker rights. While not technically certifications, these training programs are widely recognized and often required.

Other Industry-Specific Standards exist for particular sectors. For example, API standards in oil and gas, RCRA for hazardous waste management, or specific regulations for healthcare, mining, or maritime operations.

Pursuing these certifications demonstrates professionalism, provides structured learning, and often opens doors to better career opportunities. For organizations, certification shows customers, regulators, and the public that you take HSE seriously.

Getting Started with HSE: A Practical Roadmap

Whether you’re implementing HSE for the first time or looking to strengthen an existing program, here’s a practical approach:

Month 1: Assessment and Commitment

- Secure management support and budget

- Form an HSE team with representatives from different departments

- Conduct a baseline assessment of current HSE status

- Review legal and regulatory requirements

Month 2-3: Policy and Planning

- Develop or update your HSE policy statement

- Set measurable objectives and targets

- Identify your most significant hazards and risks

- Create action plans for priority issues

Month 4-6: Implementation

- Provide HSE training for all employees

- Implement control measures for identified risks

- Establish reporting and communication systems

- Begin regular inspections and audits

Month 7-9: Monitoring and Refinement

- Track performance against your objectives

- Gather feedback from workers

- Conduct internal audits

- Adjust your programs based on what you learn

Month 10-12: Review and Improvement

- Conduct a formal management review

- Celebrate successes and recognize contributions

- Set objectives for the next cycle

- Plan for continuous improvement

Remember, HSE is a journey, not a destination. Your program will evolve as your organization grows, regulations change, and you learn from experience. The key is to start, maintain momentum, and always keep improving.

Frequently Asked Questions About HSE

Q: What’s the difference between HSE and safety?

Safety is just one component of HSE. While safety focuses specifically on preventing accidents and injuries, HSE takes a broader view that also includes long-term health impacts and environmental protection. Think of safety as one pillar within the larger HSE framework.

Q: Do small businesses need HSE programs?

Absolutely. While the formality and complexity might differ, every business has a responsibility to protect workers and the environment. Small businesses often benefit from simplified approaches—less documentation, more practical focus—but the fundamental principles still apply.

Q: How much does it cost to implement HSE?

Costs vary dramatically based on your industry, size, and current state. Initial investments might seem significant—training, equipment, consultants—but remember that accidents cost far more than prevention. Most organizations find that HSE programs more than pay for themselves through reduced incidents and improved efficiency.

Q: Who is responsible for HSE?

Everyone. While HSE Officers provide expertise and oversight, safety is everybody’s job. Management must provide resources and commitment, supervisors must enforce procedures, and workers must follow safe practices and report hazards. Shared responsibility creates strong safety cultures.

Q: How do I measure HSE performance?

Use both leading and lagging indicators. Lagging indicators look backward (injury rates, lost work days, environmental incidents) while leading indicators look forward (training completion, inspection findings, near-miss reports). Together they provide a complete picture of performance.

Q: What if employees resist HSE initiatives?

Resistance usually stems from not understanding why measures are necessary or feeling that safety conflicts with getting work done. Address this through education, involvement (let workers help develop solutions), demonstrating management commitment, and designing procedures that make safe work easier, not harder.

Q: Can HSE give us competitive advantages?

Definitely. Strong HSE performance attracts customers who value responsible suppliers, helps you win contracts with HSE requirements, reduces costs through fewer incidents, improves productivity, and enhances your reputation. All of these translate to competitive edge.

Wrapping It Up: HSE as a Way of Life

Here’s the bottom line: HSE isn’t just a program or a department—it’s a way of thinking about business and how we work.

It recognises that protecting people and the planet isn’t separate from running a successful operation; it’s essential to it. Companies that get this right don’t just avoid problems—they perform better across the board. They’re more efficient, more innovative, more attractive to talent, and more trusted by customers.

Whether you’re an HSE professional, a business leader, or a frontline worker, you have a role to play. The practices we’ve discussed—from hazard identification to continuous improvement, from regulatory compliance to sustainability—work when people at all levels commit to them.

The good news? You don’t have to be perfect from day one. Start where you are. Identify your biggest risks. Take action to address them. Learn from experience. Keep getting better. That’s how successful HSE programs are built.

Remember, at its heart, HSE is about something profoundly simple: making sure people go home safe at the end of every shift and leaving the world a little better than we found it. Everything else—the policies, the procedures, the certifications—is just a means to that end.

So take what you’ve learned here and put it to work. Your people, your organisation, and the planet will thank you for it.