Every year, millions of workplace accidents occur across industries, causing injuries, fatalities, and billions of dollars in losses. What many people don’t realize is that the vast majority of these incidents are preventable. Research consistently shows that approximately 88% of workplace accidents result from unsafe acts by employees, while 10% stem from unsafe conditions in the work environment, with only 2% being truly beyond human control.

Understanding the difference between unsafe acts and unsafe conditions is crucial for creating a safer workplace, reducing insurance costs, and protecting your most valuable asset—your employees. Whether you’re a safety manager, business owner, or employee, this comprehensive guide will help you identify, prevent, and address these workplace hazards effectively.

What Are Unsafe Acts in the Workplace?

Definition of Unsafe Acts

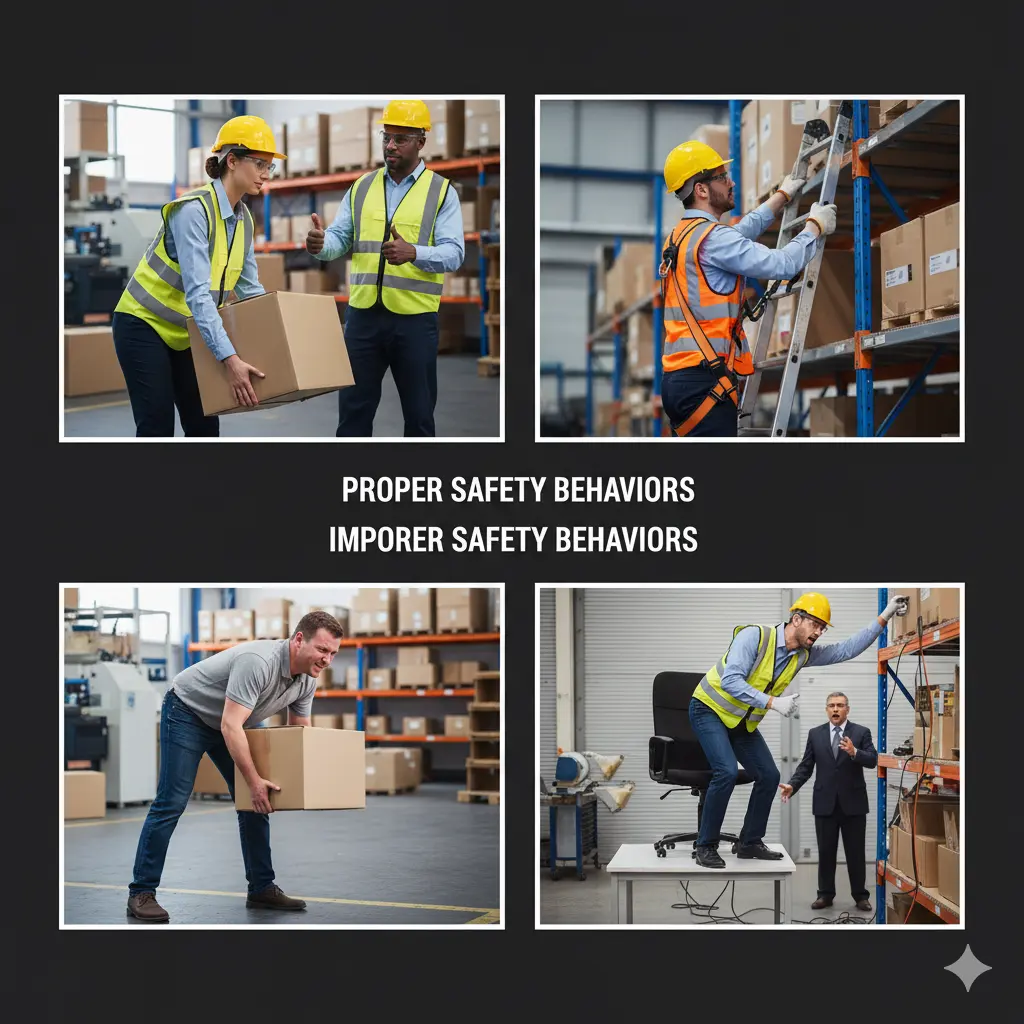

Unsafe acts are deliberate or unintentional behaviours, actions, or decisions made by workers that deviate from established safety procedures, regulations, or best practices. These human behaviours can result from poor judgment, shortcuts, lack of training, complacency, or conscious disregard for safety protocols.

Unlike unsafe conditions, which involve environmental or equipment-related hazards, unsafe acts are directly tied to human behaviour and decision-making. They represent a breakdown in the human element of workplace safety and can often be corrected through proper training, supervision, and safety culture development.

Common Examples of Unsafe Acts

Understanding what constitutes an unsafe act is essential for prevention. Here are the most frequently observed unsafe acts in various workplace settings:

Personal Protective Equipment (PPE) Violations:

- Failing to wear required safety goggles, leading to eye injuries from flying debris

- Removing hard hats in construction zones, risking head trauma

- Not wearing appropriate gloves when handling chemicals or sharp objects

- Ignoring hearing protection in high-noise environments

Equipment and Machinery Misuse:

- Operating machinery without proper authorization or training

- Using damaged or defective tools instead of reporting them

- Bypassing safety guards on equipment for faster operation

- Failing to follow lockout/tagout (LOTO) procedures during maintenance

Procedural Shortcuts:

- Skipping safety inspections to save time

- Taking unauthorized shortcuts through restricted areas

- Ignoring established work procedures under pressure

- Rushing through tasks without proper safety checks

Communication and Reporting Failures:

- Not reporting near-misses or potential hazards

- Failing to communicate safety concerns to supervisors

- Ignoring safety warnings from coworkers

- Inadequate safety briefings before high-risk tasks

What Are Unsafe Conditions in the Workplace?

Definition of Unsafe Conditions

Unsafe conditions refer to physical or environmental hazards present in the workplace that can cause accidents, injuries, or illnesses. These conditions exist independently of worker behaviour and typically require management intervention, engineering controls, or physical modifications to the work environment to address.

Unlike unsafe acts, unsafe conditions are not directly caused by employee actions but rather result from inadequate maintenance, poor design, environmental factors, or failure to implement proper safety controls.

Common Examples of Unsafe Conditions

Unsafe conditions can manifest in various forms across different industries. Here are the most prevalent types:

Environmental Hazards:

- Poor lighting in work areas, leading to slips, trips, and falls

- Excessive noise levels causing hearing damage over time

- Inadequate ventilation resulting in air quality issues

- Extreme temperatures creating heat stress or cold exposure risks

Structural and Maintenance Issues:

- Damaged flooring with holes, cracks, or uneven surfaces

- Faulty electrical wiring or exposed electrical components

- Broken or missing guardrails on elevated platforms

- Leaking roofs creating slip hazards and water damage

Equipment and Machinery Problems:

- Malfunctioning safety devices on machinery

- Worn-out tools with damaged handles or cutting edges

- Inadequate machine guarding leaving moving parts exposed

- Defective personal protective equipment

Housekeeping and Organization:

- Cluttered walkways obstructing emergency exits

- Improper storage of hazardous materials

- Oil spills or other slippery substances on floors

- Blocked fire extinguishers or emergency equipment

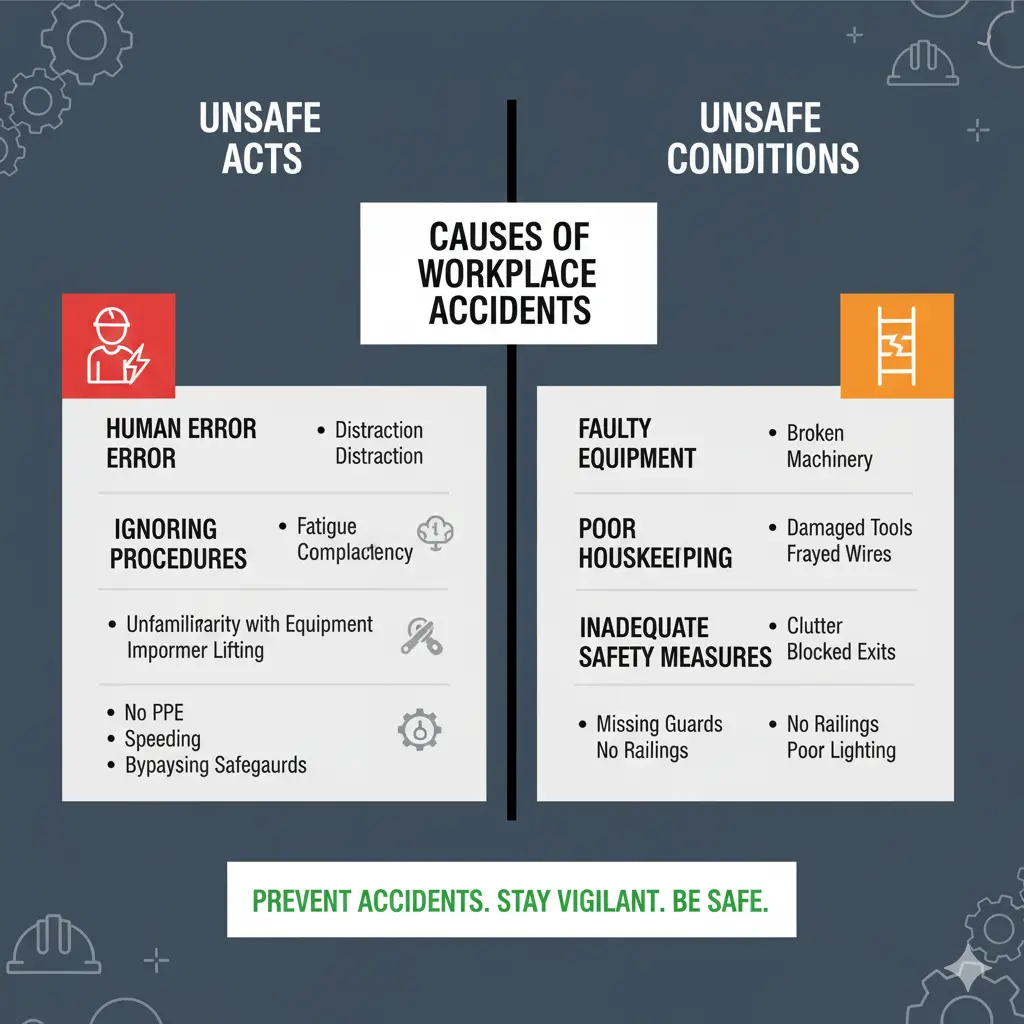

Key Differences Between Unsafe Acts and Unsafe Conditions

Understanding the fundamental differences between unsafe acts and unsafe conditions is crucial for implementing effective safety measures:

Origin and Control

Unsafe Acts:

- Originate from human behavior and decision-making

- Can be immediately controlled through employee awareness and training

- Often result from individual choices or momentary lapses in judgment

- Require behavioral interventions and safety culture development

Unsafe Conditions:

- Result from environmental, equipment, or structural issues

- Require management intervention and physical modifications

- Often persist until actively addressed through engineering or administrative controls

- Need systematic identification and correction processes

Prevention Strategies

For Unsafe Acts:

- Comprehensive safety training programs

- Regular safety meetings and toolbox talks

- Behavioral observation and feedback systems

- Creating a positive safety culture that encourages reporting

For Unsafe Conditions:

- Regular workplace inspections and audits

- Preventive maintenance programs

- Engineering controls and design improvements

- Environmental monitoring and assessment

Detection Methods

Unsafe Acts:

- Behavioral observations and safety walks

- Near-miss reporting and incident analysis

- Peer-to-peer safety monitoring

- Safety performance indicators and metrics

Unsafe Conditions:

- Systematic workplace inspections

- Equipment condition monitoring

- Environmental assessments

- Third-party safety audits

The Hidden Costs of Workplace Accidents

The financial impact of unsafe acts and conditions extends far beyond immediate medical expenses. Organizations face both direct and indirect costs that can significantly affect their bottom line:

Direct Costs

- Medical treatment and hospitalization expenses

- Workers’ compensation claims and insurance premiums

- Legal fees and potential lawsuit settlements

- Regulatory fines and OSHA penalties

Indirect Costs

- Lost productivity from injured workers and disrupted operations

- Training and hiring replacement workers

- Damage to equipment, materials, and facilities

- Increased insurance premiums and loss of reputation

- Administrative time for incident investigation and reporting

Studies indicate that indirect costs often exceed direct costs by a ratio of 4:1 to 10:1, making prevention not just a moral imperative but a sound business decision.

OSHA Requirements and Compliance

The Occupational Safety and Health Administration (OSHA) requires employers to maintain a workplace “free from recognized hazards.” This encompasses both preventing unsafe acts through training and eliminating unsafe conditions through proper maintenance and controls.

Key OSHA Requirements:

- Provide safety training in a language workers understand

- Maintain injury and illness records

- Conduct regular workplace inspections

- Provide necessary personal protective equipment at no cost to employees

- Establish procedures for reporting workplace hazards

Employee Rights Under OSHA:

Workers have the right to receive safety training, report hazards without retaliation, and request OSHA inspections if they believe unsafe conditions exist.

Effective Prevention Strategies

Building a Strong Safety Culture

Creating a workplace where safety is genuinely valued requires commitment from all levels of the organization:

Leadership Commitment:

- Visible management participation in safety activities

- Adequate resource allocation for safety programs

- Regular communication about safety priorities

- Setting clear safety expectations and accountability

Employee Engagement:

- Involving workers in safety decision-making processes

- Encouraging hazard reporting and near-miss communication

- Recognizing and rewarding safe behaviors

- Providing multiple channels for safety feedback

Training and Education Programs

Effective safety training goes beyond basic compliance requirements:

Comprehensive Orientation:

- Job-specific hazard identification

- Proper use of personal protective equipment

- Emergency procedures and evacuation plans

- Reporting procedures for unsafe conditions and near-misses

Ongoing Education:

- Regular refresher training sessions

- Updates on new safety procedures or equipment

- Lessons learned from incidents and near-misses

- Cross-training to understand interconnected safety risks

Systematic Hazard Identification

Regular Inspections:

- Scheduled workplace safety audits

- Pre-shift equipment checks

- Environmental monitoring for health hazards

- Contractor and visitor safety assessments

Employee Reporting Systems:

- Anonymous hazard reporting mechanisms

- Near-miss reporting programs

- Safety suggestion systems

- Regular safety committee meetings

Technology Solutions for Modern Safety Management

Today’s safety professionals have access to advanced tools that can significantly improve hazard identification and prevention:

Digital Safety Management Systems

- Mobile apps for real-time hazard reporting

- Automated inspection scheduling and tracking

- Data analytics for identifying safety trends

- Integration with existing business systems

Wearable Safety Technology

- Smart hard hats with environmental monitoring

- GPS tracking for lone worker safety

- Fatigue detection systems for heavy equipment operators

- Real-time air quality monitoring devices

Virtual Reality Training

- Immersive hazard recognition training

- Emergency response simulations

- Equipment operation training in safe environments

- Cost-effective training for high-risk scenarios

Industry-Specific Considerations

Different industries face unique combinations of unsafe acts and conditions:

Construction Industry

- Common Unsafe Acts: Improper use of fall protection, bypassing safety procedures for speed

- Common Unsafe Conditions: Unguarded excavations, electrical hazards, structural instability

Manufacturing

- Common Unsafe Acts: Removing machine guards, inadequate lockout/tagout procedures

- Common Unsafe Conditions: Noise exposure, chemical hazards, ergonomic risks

Healthcare

- Common Unsafe Acts: Improper lifting techniques, inadequate hand hygiene

- Common Unsafe Conditions: Slip and fall hazards, exposure to infectious diseases

Office Environments

Common Unsafe Conditions: Poor ergonomics, blocked emergency exits

Common Unsafe Acts: Improper lifting, ignoring evacuation procedures

Creating an Effective Incident Investigation Process

When accidents do occur, a thorough investigation helps prevent similar incidents:

Investigation Steps:

- Immediate Response: Secure the scene and provide medical attention

- Data Collection: Gather physical evidence, witness statements, and documentation

- Root Cause Analysis: Identify both immediate and underlying causes

- Corrective Action Development: Create specific, measurable prevention strategies

- Follow-up: Monitor implementation and effectiveness of corrective actions

Key Questions to Ask:

- What unsafe acts contributed to the incident?

- What unsafe conditions were present?

- What training gaps existed?

- How can similar incidents be prevented in the future?

Measuring Safety Performance

Effective safety programs require consistent measurement and monitoring:

Leading Indicators (Predictive Metrics):

- Number of safety training hours completed

- Percentage of hazards reported and corrected

- Safety observation and inspection completion rates

- Employee safety perception survey results

Lagging Indicators (Outcome Metrics):

- Injury and illness rates

- Workers’ compensation costs

- Number of OSHA citations

- Lost time due to accidents

Building Your Safety Action Plan

To effectively address unsafe acts and conditions in your workplace:

Short-term Actions (0-3 months):

- Conduct comprehensive workplace hazard assessment

- Update safety training programs based on identified gaps

- Implement anonymous hazard reporting system

- Establish regular safety inspection schedule

Medium-term Goals (3-12 months):

- Develop behavior-based safety observation program

- Upgrade outdated equipment and address structural issues

- Create safety committee with worker representation

- Implement safety performance measurement system

Long-term Strategy (1+ years):

- Build comprehensive safety management system

- Integrate safety considerations into business planning

- Develop advanced safety technology solutions

- Achieve industry-leading safety performance metrics

Conclusion: Creating a Safer Tomorrow

Understanding the critical distinction between unsafe acts and unsafe conditions is the foundation of effective workplace safety management. While unsafe acts require behavioral interventions and cultural change, unsafe conditions demand systematic identification and physical corrections. Most importantly, preventing both requires a comprehensive approach that combines strong leadership, employee engagement, proper training, and continuous improvement.

Remember that workplace safety is not a destination but a continuous journey. By focusing on both the human factors that lead to unsafe acts and the environmental factors that create unsafe conditions, organizations can create workplaces where every employee returns home safely each day.

The cost of prevention will always be less than the cost of accidents—both in human suffering and financial impact. Start today by conducting a thorough assessment of your workplace, engaging your employees in safety conversations, and committing to the systematic elimination of hazards.

Your employees, your bottom line, and your community will all benefit from your commitment to workplace safety excellence.